Products

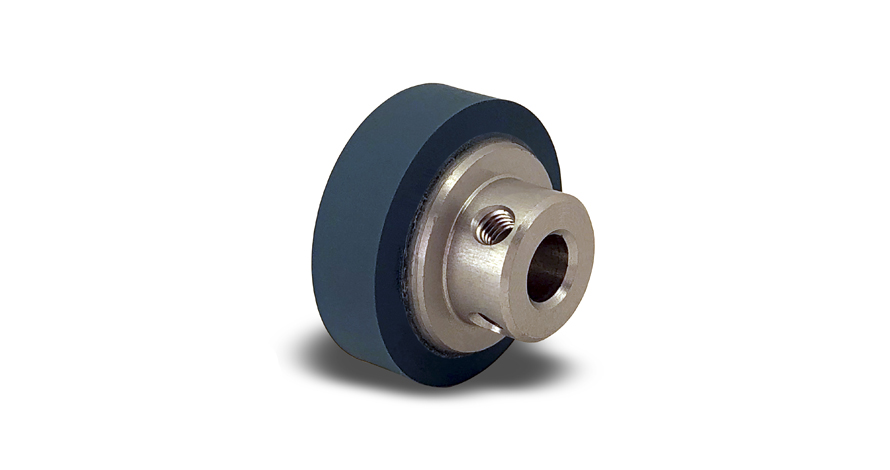

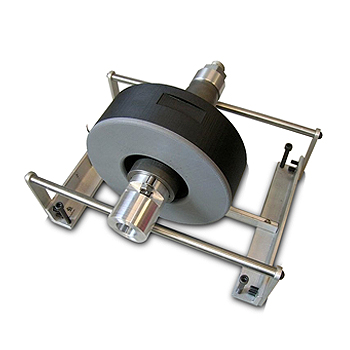

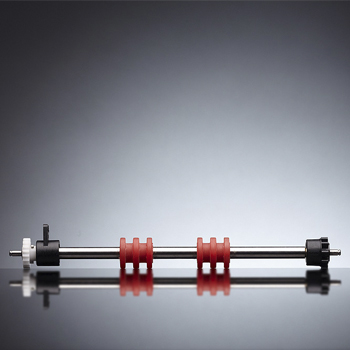

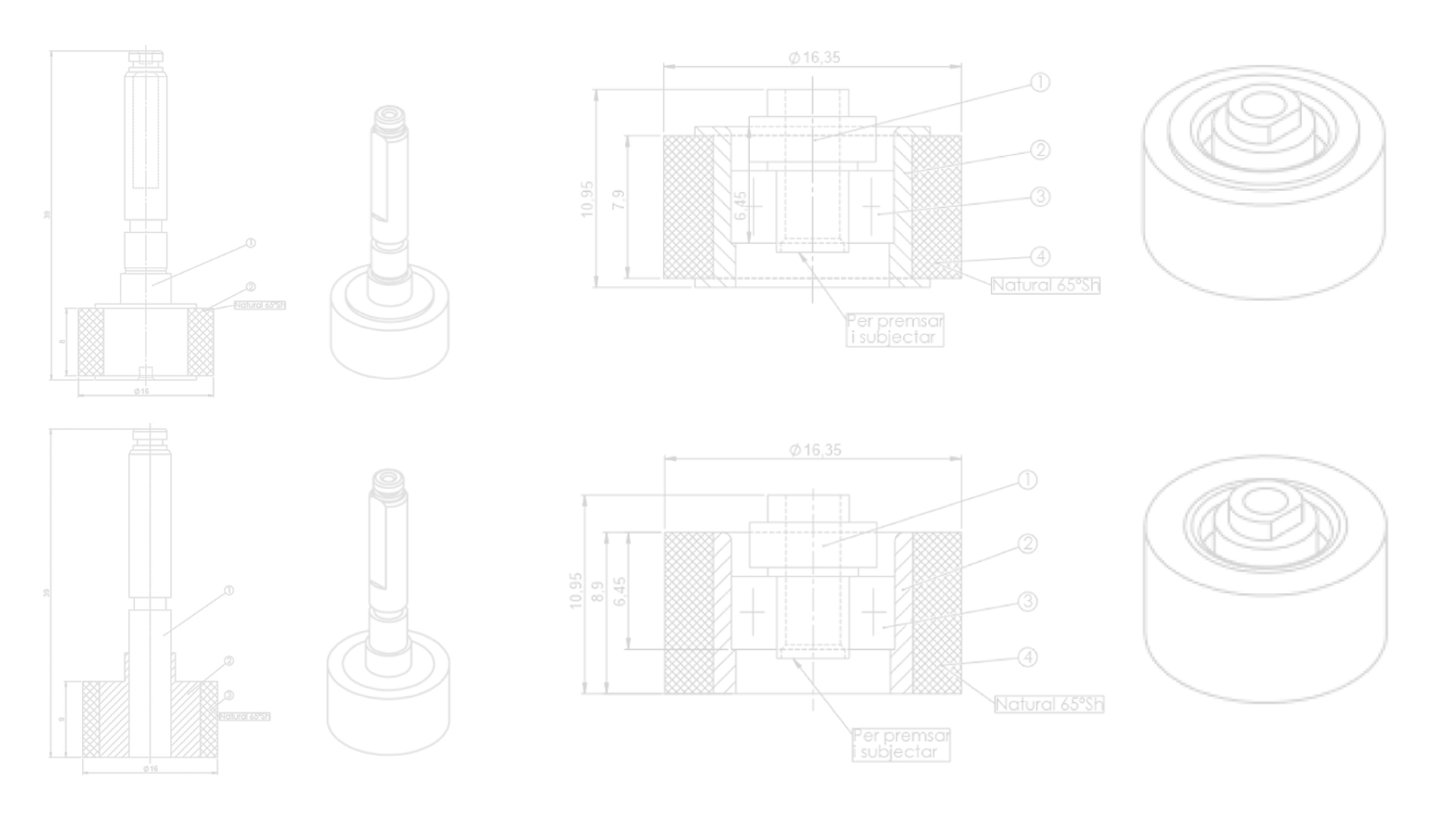

Rubber rollers

METALTEX S.L – specialists in manufacturing and development of drag systems for access control, ticket printing, ATMs, card readers, banking machines, ticket vending machines and packaging machinery.

With more than 100 standardized references and flexible manufacturing, Metaltex S.L poses a complete range of products and a great capacity to develop new solutions.

We have concrete solutions for each application, with excellent technical assistance and with highly competitive prices. All this is supported by our activity with large companies in the sector.

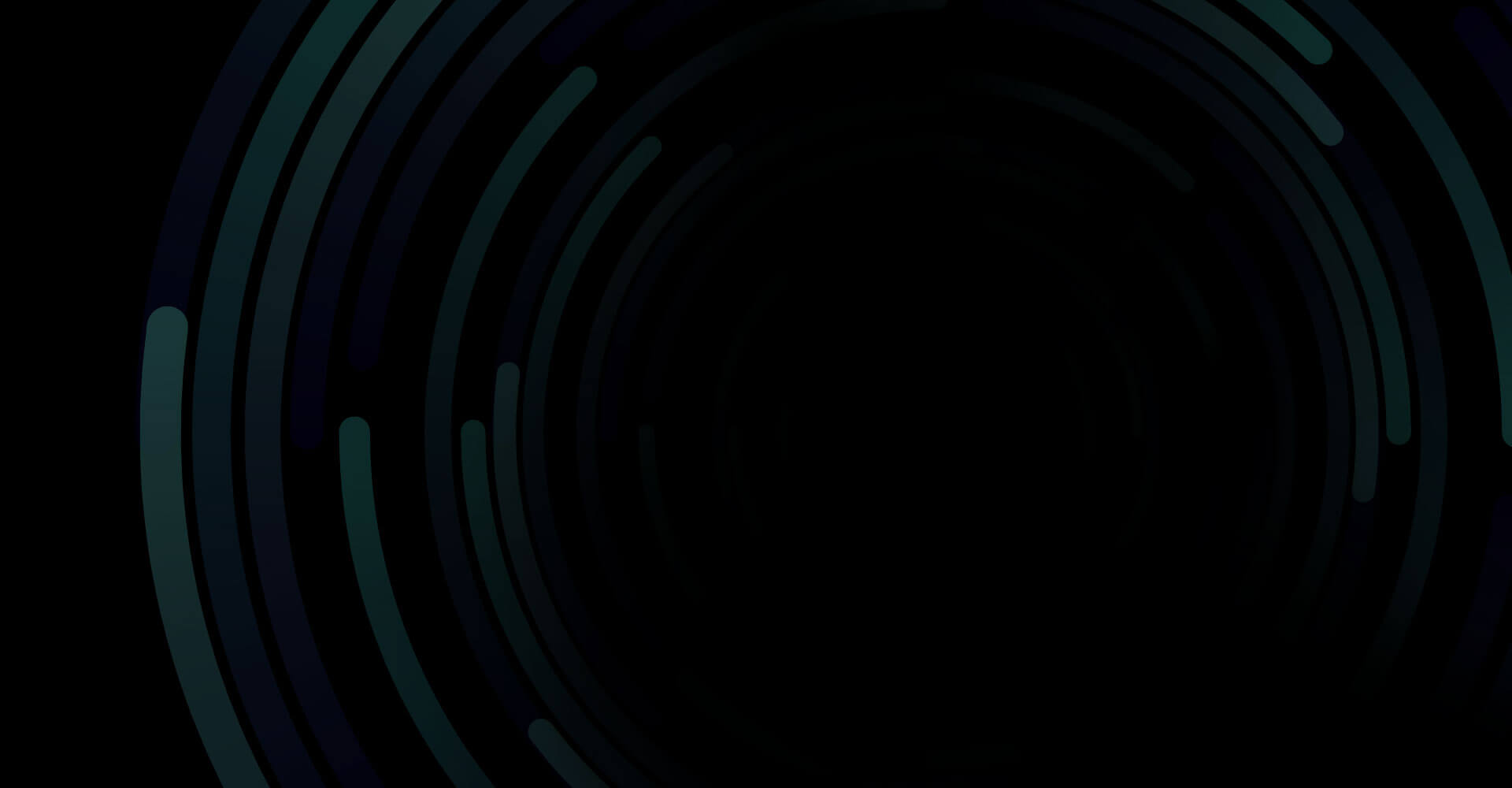

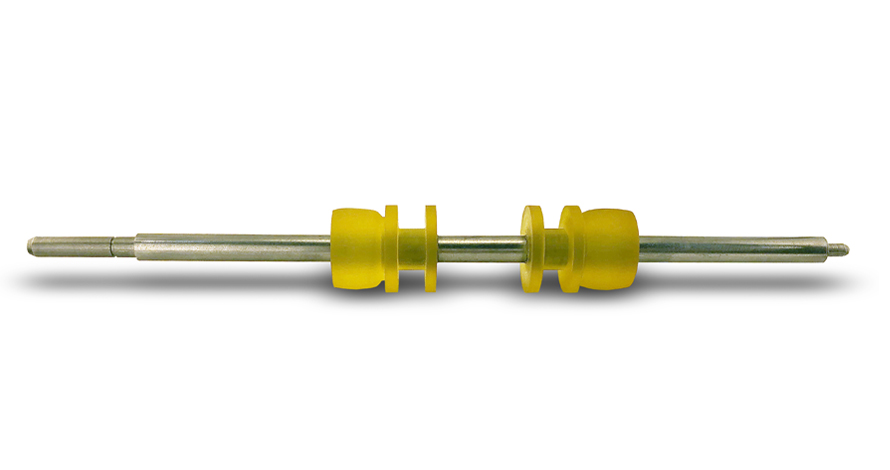

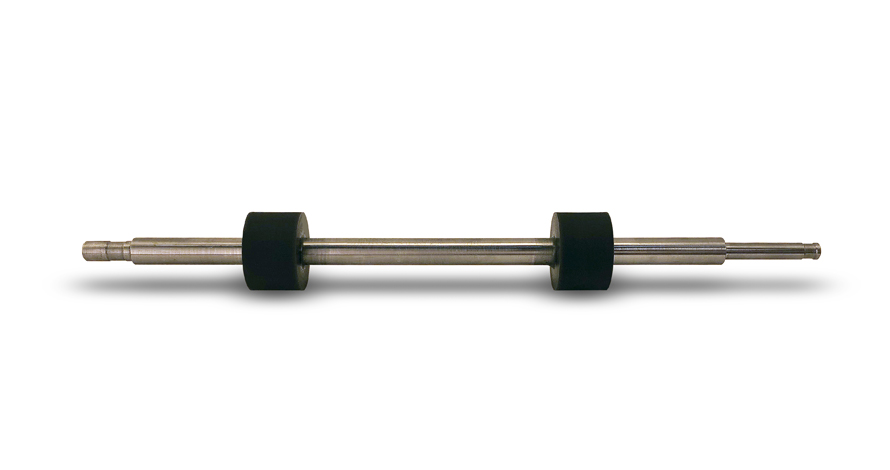

Today, drag systems use rubber drag capacity as the main technology, in fact, the most common applications use small wheels or rubber-coated axles. Therefore, the solution to be developed requires two clearly differentiated components:

- The core: Depending on constructive and functional aspects, material, dimensions, tolerances, etc. are defined.

- The coating to be used: On the basis of the element to be dragged, to the necessary performance and the function to be performed, parameters for each element were defined as: type of rubber, type of fixing of the coating, thickness of the coating, type of grinding, hardness , etc.

Design

METALTEX S.L has a technical department dedicated to the control, support and advice of productive tasks and the development of R&D designs and processes.

Our technical department places special emphasis on design with a very personalized treatment with the client, in order to give very personalized solutions to each element we design. We have CAD stations and licenses of AutoCAD® and SolidWorks®. We manage and supervise the project to be carried out from our technical department making the necessary tests to reach a good product completion.

R&D Processes

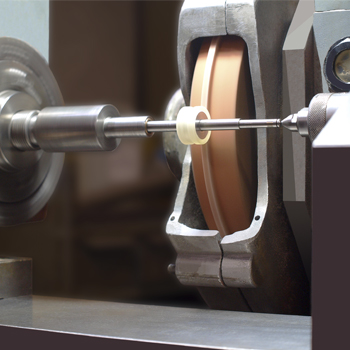

Production

With the aim of achieving an optimal price-quality commitment METALTEX S.L has positioned itself as a productive company oriented towards total customer service.

The Productive Department allows us to:

- Prototyping, trials and studies in development processes or R&D.

- Own manufacturing of our products ensuring continuous improvement and an exhaustive quality control oriented to zero defects.

- Support to the sales department in semi-billed products, machinery maintenance, urgent repairs.

The consolidation of a young and dynamic work team has facilitated the constant integration of machinery in response to the continuous market demands. Our means of production include everything from robotic CNC lathes to machining centers and conventional machinery aimed at typically artisanal work.

OUR COMPANY

Contact

Fill out this form with your information and the message with the question you need to send us. We will reply as soon as possible.

CALL US

937 855 312

OR WRITE TO